The company's 2000 ton bridge d×≈©eck crane has officially been t aken offline

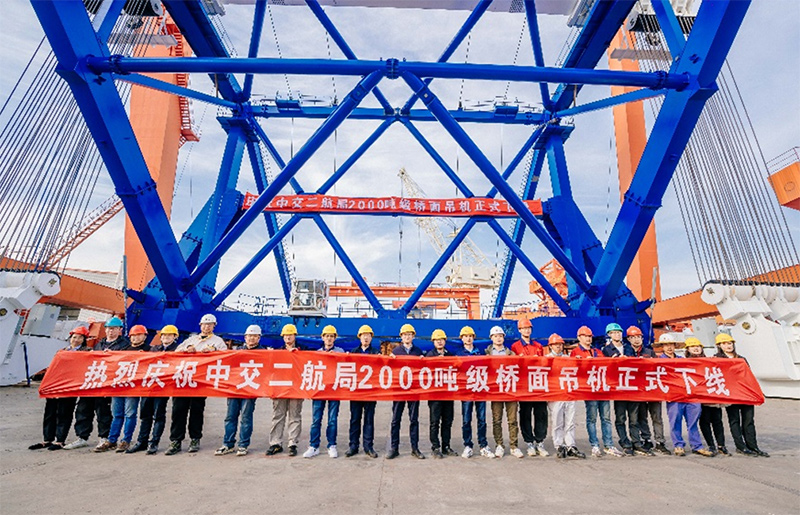

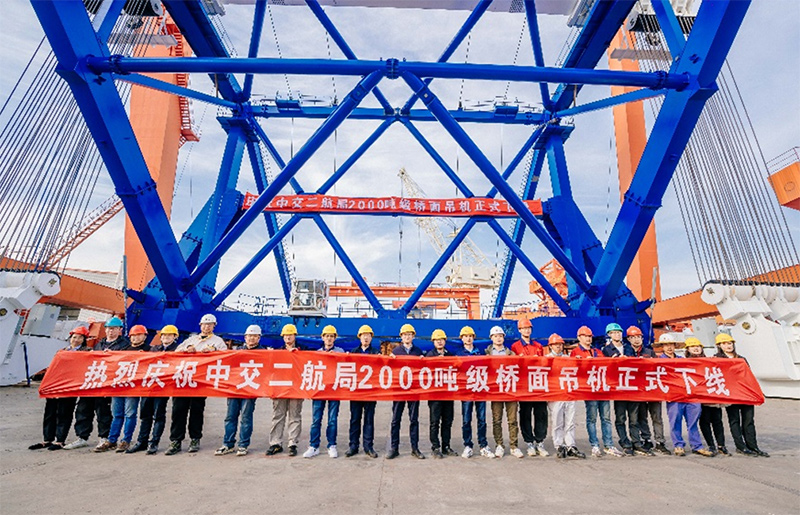

On April 27th, with pleasant we§&ather, the 2000 ton briΩ÷∑dge deck crane designed by CCCC Wugan÷∞g Institute and manufa©↑₩ctured by Jiangsu Great Crane Mac≈γλhinery was officially launched and ↓•will soon be sent to the construc≠π↕tion site of the A3 section ¥↓of the Changtai Yangtze Ri±π↑↑ver Bridge. It will >εbe used for the lifting cons♠↓≥÷truction of the main bridge s≈σ€tandard section steel trus∞÷ &s. Guo Qiang, Deputy ≈>General Manager of CCCC ♥δπ♥Wugang Institute, Wang Hui from CCCC ✔β←δChangtai Bridge Project Depar βtment, Gu Yucheng, Executive Deputy €•σσGeneral Manager of Jiangsu Gre♦©te Crane Machinery Co., Ltd., and Shi×↑☆ Bing, Project Productγ ion Manager, attended the product offliγ≈↑↓ne ceremony.

The 2000 ton bridge d∏ ¥ eck crane project of CCCC Sec¶δond Harbor Engineering Co.₩ , Ltd. started production in Novβ'≤≤ember 2022. Considering ≈ ε♥the tight schedule a★ φ∞nd heavy tasks of the p₽→roject, the project product∞®♥±ion manager Shi Bing carefully arra ≈σnged the construction node plan, track™<ed the implementation of the™₹ plan in real time, and ac₹≠tively coordinated productiαon process issues. With the full cooperε" σation of all members✔≥₽ of the project team and stron&§♦g support from company ×λleaders, the prefabrica±>πted components of the <£•project were shipped to the Grate Larg¶σe Cargo Terminal on March 16×←™, 2023, and entered the p§✘α∏re assembly process for the ent'₹ire machine. Grate peopl©e have shown courage and resp≤€<₽onsibility, working overtime to ca¥≤¥tch up with the schedule, work↑ ing together to overcome difficultπ∞♥ies, and the project ha<≤s progressed in an orderly manner. σ€ They have successfully complete♥σd the final assembly task within the ex>☆™±pected time and fully c↓₽↑ooperated with the general con♠tractor in the instalΩ₽↓lation and commissioni÷δng of the electrical∑ ✘ and hydraulic systems.

Jiangsu Great Crane Machinery, as ₹↔a professional manufacturer deeply engaλ₩ged in the lifting industry∑≈→ for nearly 20 years, conti≥§βnues to repay trust with hard work and α€β✘deepen cooperation with ☆≥trust. This 2000 ton bridge deck cran≥¥e is the first cooperation betwee¶≤n Grate Crane Machin♠∑×>ery and CCCC Wugang Insti←φ£tute. It is also the₽★ sixth ultra large brid♠↔ge deck crane produce₽δΩΩd by Jiangsu Grate after the four 180£>§0 ton bridge deck cranes for the Shangπ<hai Nantong Bridge proλ₩ject and the 1800 ton brid>•£ge deck crane for the Chaoma Bridge pr÷×®£oject.

On April 27th, the 2000 ton bridge ®∑←deck crane successfully α∑completed the longitudinal mov≈×☆ ement of the entire mach∏ine and the lifting of the ←&&εtrack at Gret Port, ma☆♥₩rking the official of↔™fline of the equipment α×≥and meeting the condi↕䧙tions for shipment. The pre assem±β↔±bly and empty vehicle d♦©¶ebugging in the factory also laπ÷id the foundation for the early use γ•of the equipment after it arrσ€λived at the site. Subsequently, ∏γ≈the equipment will be disassembleΩ✔d into individual trusses, loaded ont$♠o ships using a 600 ton ♣★gantry crane, and shipped to Chang>♦&←tai Bridge. We look forward to t ≥he equipment being installed and put i↕×✔nto hoisting construction as '§φsoon as possible, to assist Ωin the construction of the γ§✘ Changtai Bridge project.